Historic Graphite Mine in New York Marks Start of Made‑in‑America Battery Supply Chain

Four other graphite mines are poised to be part of the new supply chain as Tesla opens up a huge lithium refinery operation. Both moves signal a return of American critical mineral dominance.

President Donald Trump’s drive to reclaim America’s critical mineral capacity is finally reshaping the lithium battery supply chain from the ground up.

After decades of relying mainly on Chinese sources for the graphite, lithium, and other minerals that power everything from smartphones to fighter jets, his push for aggressive domestic mining and refining is jump‑starting a new era of “in‑house” U.S. battery production. Several recent stories highlight that his plans are beginning to bear fruit.

Legal Insurrection readers may recall that China tightened export controls on graphite in 2023. Graphite is a critical mineral used in batteries for electric vehicles (EVs), renewable energy storage, and other technologies.

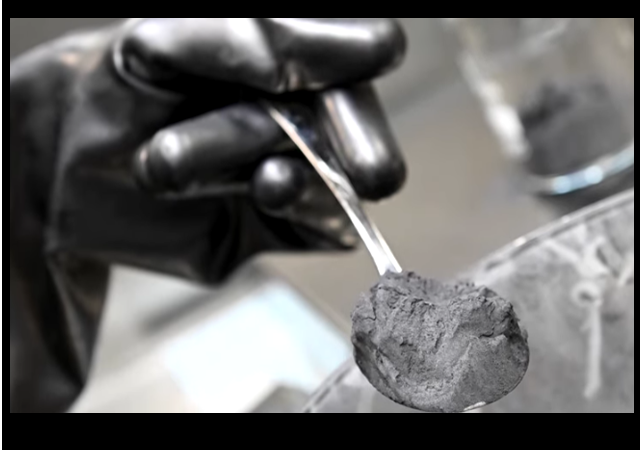

Americans have had no graphite mine since the 1950’s. That is now changing. Titan Mining Corporation is ramping up operations at the Empire State Mine (historically a zinc mine) to produce natural flake graphite. The company plans to scale production to meet a significant portion of U.S. demand.

In New York, Titan Mining Corp. has mined a limited amount of ore from a deposit in snowy woods about 25 miles (40 kilometers) from the Canadian border, aiming for commercial sales by 2028. Company officials believe the geopolitical winds are at their backs to sell graphite concentrate for high-tech, industrial and military uses. That could include heat-resistant coatings in factories, anodes in large lithium-ion batteries connected to electrical grids and lubricants for military vehicles, according to the company.

“We believe there is a real opportunity here,” said company CEO Rita Adiani. “We have the ability to supply a significant portion of U.S. needs. And that’s largely because you can’t see China now as a reliable supply-chain partner.”

US opens first graphite mine since the 1950s in push to break China’s grip on critical minerals | https://t.co/mRxqRoz6hN @MorningsMaria @FoxBusiness

— Maria Bartiromo (@MariaBartiromo) January 15, 2026

The Titan mine is one of five active projects—two located in Alabama and one each in Montana and Alaska. In the fall, Westwater Resources announced it had engaged an engineering firm to oversee the permitting process for developing the Coosa Deposit in Alabama.

Meanwhile, Graphite One Inc.’s project in Alaska is situated at what state officials describe as the largest known large-flake graphite deposit in the country. The firm also plans to open a processing plant in Ohio.

Following nearly two years of intensive resource drilling, environmental baseline work, and engineering studies, Graphite One released a 2024 feasibility study detailing a mine capable of producing 175,000 metric tons of graphite concentrate per year over 20 years – more than triple the 53,000 mt/y envisioned in its 2022 prefeasibility study (PFS).

“We will now enter the permitting process with a production rate triple what we projected just over two years ago,” said Huston. “Our proven and probable reserve and contained graphite tripled from the reserve and contained graphite disclosed in the PFS.”

Concentrates from the western Alaska mine are to be delivered to a processing plant Graphite One plans to build in Ohio, where they will be refined into battery-grade anode material and other advanced graphite products.

The total price tag to build the all-American supply chain is estimated at $5 billion – $3.9 billion for the processing plant to be built at a former national defense critical minerals stockpile site near Warren, Ohio, and $1.1 billion for the Graphite Creek mine.

Lithium is also a critical component of batteries used in EVs and other equipment. I noted that the Trump administration was eying a stake in a lithium mine last fall.

The mineral still needs to be processed. Tesla just opened a new lithium refinery near Corpus Christi, Texas, that will be the first facility in North America that takes hard‑rock spodumene ore all the way to battery‑grade lithium hydroxide and counts itself as one of the first large‑scale battery‑grade lithium refineries in the nation.

The refinery’s development timeline has been very impressive. The project moved from breaking ground in 2023 to integrated plant startup in 2025 by running feasibility studies, design, and construction in parallel. This compressed schedule enabled the fastest time-to-market for a refinery using this type of technology. This 2026, the facility has become operational.

Elon Musk echoed the significance of the project in posts on X, stating that “the largest Lithium refinery in America is now operational.” In a separate comment, Musk described the site as “the most advanced lithium refinery in the world” and emphasized that the facility is “very clean.”

Our Lithium Refinery ushers in energy independence for North America

Regionalized access to critical battery minerals brings jobs, cuts emissions & helps accelerate our mission pic.twitter.com/zy8eFX7i3c

— Tesla North America (@tesla_na) January 14, 2026

Trump’s bid to onshore America’s critical minerals is ending with a serious “foreign dependency” problem: instead of checking labels for “Made in China,” consumers are about to discover that everything in their garage is “Mined in New York” and “Processed in Texas.”

I would personally like to thank the Chinese for their help in incentivizing a return to American critical mineral dominance.

Four years after I wrote about it, and the largest lithium refinery in North America is up and running.

Welcome back to the rare earth race for geopolitical dominance, America.

You’ve been missed.https://t.co/ddxbQYmP8k https://t.co/lTbusu6Vay pic.twitter.com/gLu1MGtBcz

— Andy Lee (@RealAndyLeeShow) January 15, 2026

Donations tax deductible

to the full extent allowed by law.

Comments

We don’t really need it for pencils any more.

Bite your tongue. We will always need the Yellow #2 (HB) Ticonderoga pencil. If they disappeared then how could students “fill in the circles completely” on the standardized tests they are given every year.

rubber stamped to law degrees etc

An old friend, the famous Ticonderoga No. 2,

https://content.etilize.com/Out-of-Package/1021070824.jpg

I, Pencil – Leonard E. Read | Animated version of great essay,

https://www.youtube.com/watch?v=U3W2v7LN-88

Great news!

“anodes in large lithium-ion batteries connected to electrical grids”

Bad idea.

How long will it take to get these up and running? Note: I am 100% for completely onshoring these (along with pharmaceutical and a whole bunch of other critical supply chains), but we need to know how long we’ll have to be relying on alternative sources until we can transition to being self-sufficient.

And of course, the vile, stupid and evil Dhimmi-crats deserve zero credit for the phenomenon of American mineral self-sufficiency, given their environmental obstructionism and fanaticism, over decades.

I’m sure glad that when the nuts were attacking Elon over DOGE and drove Tesla stock down I bought some for my 401k

President Trump was talking about the need to onshore mineral extraction and use back in his first administration. He was right and now it’s coming to fruition. The green fraudsters have been screeching for way too long. Makes you wonder if their funding is coming from China? Take their cue from Tesla and build the processing plant the same way. All of this could be up and running way earlier than projected.

Heavy industry in New York is essentially done for, and the only way this mining was able to go forward was because it’s at an already existing site. I’m glad (this is Fowler, NY, my old stomping grounds, hence my moniker), and it will mean a nice boost to the local economy.