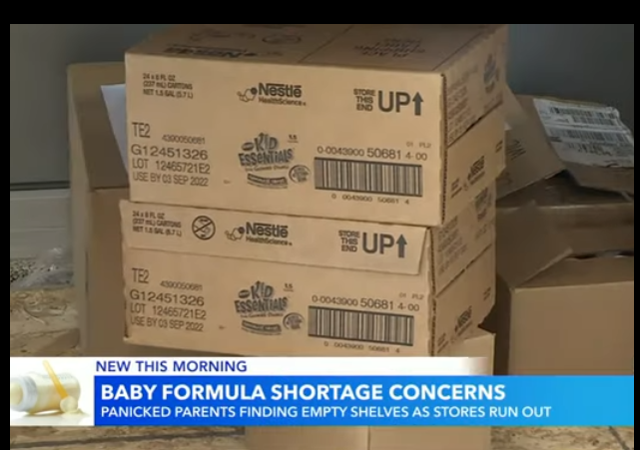

Abbott Plant, at Heart of America’s Baby Formula Shortage, Reopens

FDA announces plans to help allow foreign baby formula manufacturers to stay on the U.S. market with long-term authorization.

Finally, there is some good news on the baby formula shortage crisis.

Abbott Laboratories’ Michigan plant has been shutdown by the Food and Drug Administration (FDA) over the past few months. Its closure led to the nationwide shortage of baby formula, as it was the nation’s leading maker of formula in a market that has been tightly controlled to prevent foreign supplies from entering.

The company on July 1 assumed operations at its Sturgis, Michigan baby formula plant, which was closed last month due to heavy rains, a company spokesperson told Reuters on Saturday.

The company saw its Sturgis facility shuttered by the Food and Drug Administration in February after two infants died from a rare bacteria which may have come from the plant.

At the time, it also recalled infant formula products, including Similac, in response to reports of bacterial infections in babies who consumed products made at the facility.

Before the recall, Abbott controlled 40% of the infant formula market.

The company indicates it will begin producing the specialty formulas that have been in short supply.

Abbott had said it would restart EleCare production, followed by specialty and metabolic formulas, after it reopened.

The plant had previously been shut down for months after an FDA inspection that found Cronobacter sakazakii bacteria, which can be deadly to infants, in several areas. Similac, Alimentum and EleCare powdered infant formulas made at the plant were recalled, and the closure exacerbated shortages caused by supply chain disruptions. Families across the United States have struggled for months to find formula for infants and for people with specific nutrition needs.

Production had been underway for less than two weeks before the closure from the storm.

More than 20% of formula products — powder, ready-to-drink and liquid — have been out of stock for the past month, according to data through July 3 from market research firm Information Resources Incorporated (IRI).

The FDA has also announced plans to help allow foreign baby formula manufacturers to stay on the U.S. market with long-term authorization, to broaden market options and prevent shortages from occurring again.

The FDA aims to provide a path for overseas producers that have already sent supplies to the U.S., under temporary emergency approval, to stay on the market by meeting existing requirements. The plans also will make it easier for new importers to navigate the FDA’s regulatory review process.

“The need to diversify and strengthen the U.S. infant formula supply is more important than ever,” FDA Commissioner Dr. Robert Califf and Susan Mayne, director of the agency’s Center for Food Safety and Applied Nutrition, said in a statement. “The recent shutdown of a major infant formula plant, compounded by unforeseen natural weather events, has shown just how vulnerable the supply chain has become.”

DONATE

DONATE

Donations tax deductible

to the full extent allowed by law.

Comments

I predict a giant sucking sound. after those hungry babies get their bottles

The sound you heard is the sucking sound as half the supply is sucked up and shipped to the border.

Of course there are no border guards to help with distribution as they have all been disciplined for holding reins while on horseback.

Any of those kids named Ross?

There was one named Betsy wearing a flag on her diaper.

Some boxes are marked “dn” with an arrow pointing down. They ought to standardize it.

It’s Abbott’s Michigan plant. The boxes you see are destined for the upper peninsula.

Regulatory negatives and an epiphany in market awareness.

The bacteria that killed the children did not come from the plant. Multiple and extensive sampling by the FDA and Abbot found no Cronobacter sakazakii in the infant packaging area, an enclosed portion of the building. 5 samples outside the sterile area, but inside the building were found. None matched the genetic profile of the bacteria that killed the infants.

The FDA’s acts were irresponsible and negligent in the extreme. Just as is the FDA’s roadblocks to allow more manufacturers in this field. Again we see horrendous indifference, callousness, corruption, and incompetence by the FDA.

“The FDA’s acts were irresponsible and negligent in the extreme.”

The Cliffs Notes on “Atlas Shrugged For Dummies.”

Ok, one disaster from the pedophile-in-chief and his retarded administration finally fixed.

Not fair to count the ones OTHER people had to fix.

The plant was closed due to “heavy rains”? WTF is this? Rain isn’t an “unforeseen weather event”, and it’s generally a trivial irritant in the modern day. If there was heavy flooding in the area, why not say so?

They did say so. ( heavy flooding)

Just as an FYI, there are many plants ( of various varieties) that are fine during a “rain” but when a real storm comes by ( which overwhelms sumps, pumps, berms ad sanitary sewers and ponds) cause shutdowns.

In the case of a food/drug processing facility, the “contamination” from such an event ( and possibly stock spoilage) triggers a number of decontamination protocols before a start-up is allowed.

One hours worth of production from this facility will make more formula than ever single aircraft worth of formula the US flew over from Europe in their public relations kabuki theatre.